A 3D printer is a device which uses 3D printing technology to ‘print’ or create objects with the printed object being built layer by layer. Imagine a vase which has been cut into thousands of horizontal layers. The 3D printer will build up that vase using those layers by placing one on top of the other at a time. The process of 3D printing is also known as “additive fabrication” or “additive manufacturing”.

##Print 3D

The process of 3D printing or additive manufacturing is a major advancement in the manufacturing of objects. This is because current manufacturing procedures generally involve the reduction or the alteration of the material in question in order to create the desired object. In addition, these procedures also require a significant amount of machinery and a considerable number of qualified personnel..

3D printing starts with the creation of a “3D design”. More commonly known or 3D model, this file is the digital representation of the object that will be printed. This 3D file is then sent and read by the 3D printer. The internal software of the 3D printer sends instructions to the machine and begins to fabricate the desired object layer by layer.

##The 3D model

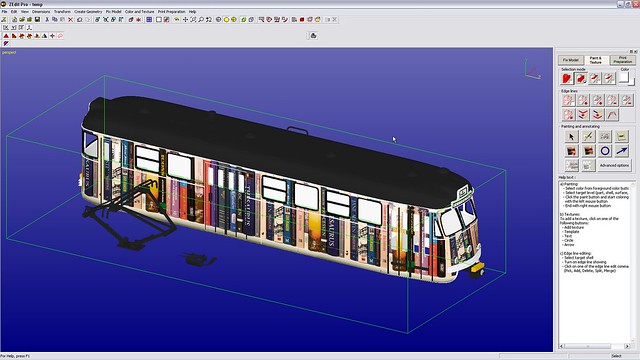

3D printing involves the use of a digital file known as a 3D model which is created using modelling software which belongs to two main categories: Those intended for professional purposes particularly in the fields of engineering and architecture (CAD type OPENSCAD software, Solid works) and those intended for private clients which are significantly more user friendly and easier to use (Google SketchUp, Tinkercad, Autodesk 123D ).

source: Creative Tools via Flickr

source: Creative Tools via Flickr

It is possible to obtain a 3D model by digitizing an object through the use of a 3D scanner which creates a 3D digital model using the actual model in the same manner that a 2D scanner creates a digital file from a document.

Numerous 3D scanners such as Makerbot Digitizer and Fuel3D are now being manufactured for general use although 3D scanners such as ReconstructMe were initially created for professional use.

There are also applications such as 123D Catch Autodesk which make it possible to generate 3D models using pictures taken by a smartphone! Creating a model using designated software or a scanner makes it possible to obtain a 3D file which contains important information including the dimensions and the size of the object. This file is commonly known as an STL file (an abbreviation of Stereolithography). The STL file is then read by the software which runs the 3D printer (known as G-code generator) which divides the 3D model into minutely fine horizontal layers in the same manner an IRM divides the human body into “slices”. This internal software proceeds to send instructions to the printer which then begins to create the required object starting from the base until the top is reached.

##How do 3D printers work? The functionality of a 3D printer is complex with over a dozen different technologies dedicated to 3D printing currently in existence. In spite of their differences, however, these technologies all function according to the same principle: the creation of an object layer by layer using the material provided according to instructions provided by the software which runs the printer. The main distinguishing feature of these technologies lies in the manner in which the material is layered, with there being three main classifications of 3D printers which are as follows:

### Home 3D Printer This group includes printers which deposit material that has been melted or is in semi-liquid form from the print head. It includes personal printers such as the Makerbot Replicator model with melted plastic being one of the most commonly used materials.

### Industrial 3D Printer This group includes printers which create objects using a photopolymer originally in liquid form which solidifies when exposed to laser rays or to light. Of all the three groups of printers it is the earliest to have been made and has experienced considerable commercial success due to its high quality of printed products.

The third group includes printers which manipulate material in powdered form through the use of a liquid adhesive or exposure to laser rays. Printers belonging to this group offer a number of benefits including an ability to use a wide range of materials in the creation of objects such as nylon, ceramic, wax, bronze, stainless steel and titanium.

Once the printing process has been completed, objects which have been produced may have small blemishes or scratches. For ceramic objects produced through this process, it is possible to eliminate such blemishes using varnish while objects made of resin, plastic or metal may be painted or polished.

source: Shapeways via Flickr

source: Shapeways via Flickr

Due to modern design techniques, there are now 3D printers which are capable of achieving layers as thin as 16 micrometres as well as printers which are capable of effecting the stratification process more efficiently.

In 3D printing, issues of quality and resolution are based on similar principles to those related to standard paper printing with better results being achieved with smaller objects. For larger sized products the manual removal of material is required in order to produce a finer finish. The numerous improvements in 3D technology in recent years has made the production of varied objects more cost-effective.

3D printers offer a wide range of benefits. For example it is possible to create replacement products for domestic purposes. Professional and industrial 3D printers are capable of creating equipment for producing and manufacturing prosthetics used in the fields of medicine and dentistry.