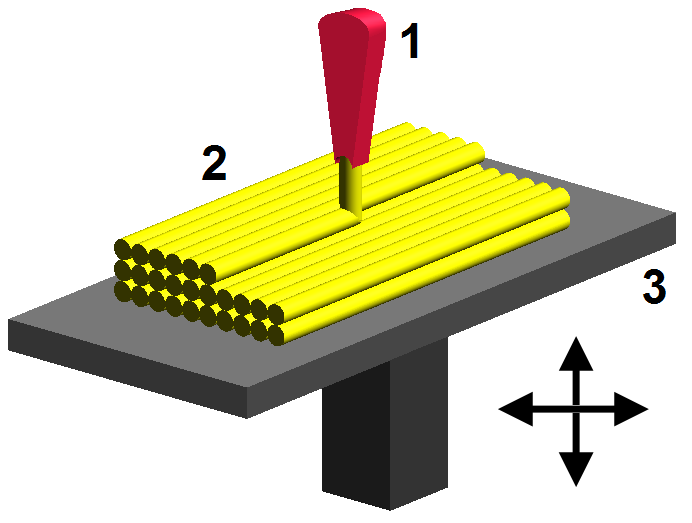

** Fused Deposition Modelling (also known as FDM) makes it possible to print 3D objects using ‘threads’ of material. Plastic is one of the fused deposition modelling materials most commonly used. The fused deposition modelling process involves the distribution of melted plastic, layer by layer using a moving extruder in order to build the required object and is at present, mainly used by home 3D printers.**

Once the fused deposition modelling machine receives a 3D digital model, its print head begins to move along the length and breadth of the printing platform, heating the thread made from the fused deposition modelling material and melting it in order to distribute it as required and create a layer. Once a layer has been created, the print head is raised by a height corresponding to its thickness and repeats the process once again until all the layers provided by the 3D model have been formed. Once the fused deposition modelling process has been completed, the object is left to cool and harden.

source: Zureks via Wikipedia

source: Zureks via Wikipedia

The main benefits of this procedure are Fused Deposition Modelling costs and its simplicity of use. Fused deposition modelling disadvantages however include a reduced printing quality compared to standard printing procedures such as Laser Sintering or stereolithography in spite of reduced costs. Fused deposition modelling machines range between 400 euros and 80 000 euros (for more sophisticated models) in price and hence are significantly easier to acquire than 3D laser sintering printers which start from 80 000 euros. The majority of fused deposition modelling machines currently priced between 500 and 3000 euros are capable of providing printed objects of satisfactory quality although they would be unsuitable for creating prototypes or finished items.

| Property | Fused Deposition Modelling |

| Abbreviation | FDM |

| Type of material | Strong Filament |

| Available materials | Thermoplastics such as ABS, Polycarbonate, and Polyphenylsulfone; Elastomers |

| Maximum object size (in cm) | 92 x 61 x 92 |

| Minimum characteristic size (po) | 0.005 |

| Maximum Resolution | 0.0127 |

| Tolerance (in cm) | ±0.0127 |

| Finishing | Rough |

| Printing speed | Lent |

| applications | Form/fit testing, Functional testing, Rapid tooling patterns, Small detailed parts, Presentation models, Patient and food applications, High heat applications |